MCC IDE

For G+, Python and C/C++ programming, embedded operation and machine management

MCC IDE

For G+, Python and C/C++ programming, embedded operation and machine management

MCC IDE

MCC IDE

Previous

Next

In order that workers can program for their machines in field and manage their production lines more efficiently, we have developed the MCC software.

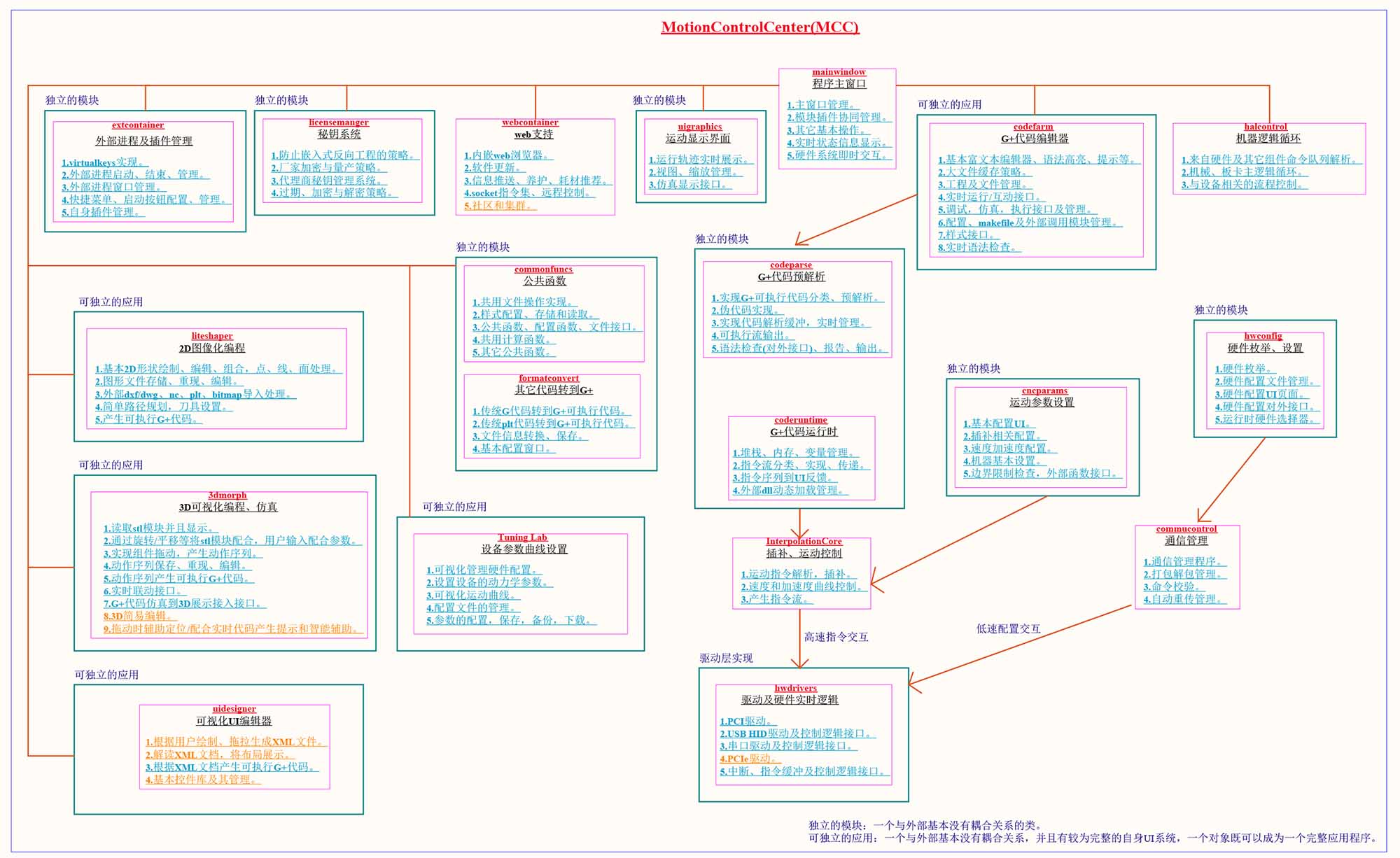

MCC (Motion Control Center) is a complex and powerful integrated development environment for G+, Python and C/C++ programming languages, as well as an embedded operation and management software kit of the industrial equipment. It comes with the program editing, simulation, execution, graphic and 3D design, UI design, online shop, device operation management, hardware parameter setting, hardware link and driver management, etc.

Here shows the interface and main menu of MCC.

Previous

Next

Tuning Lab is a module of MCC for users to set the motion parameters of the machine visually. For example: pulse equivalent, acceleration and deceleration curve, maximum speed and acceleration speed, maximum impulse, inertia of each direction.

Tuning Lab enables the user to control every detail of the curvilinear motion and promotes the embedded predictor to work efficiently.

Previous

Next

Topological structure and bus connection of G+ system.

The G+ system supports a variety of topologies, which may or may not include the X86 host, may or may not include the G+ host, and any G+ module can be interconnected or work alone.

The HX PLC modules implement the functions of the G+ system. See HX PLC link for details.

The G+ bus includes serial chains for enumerating and configuring hardware; includes EZIO for remote IO interconnection; includes high-speed parallel buses and fiber optic cable terminals.

MCC includes the following modules and external extensions:

[ext-container] [license manger][liteshaper] [3dmorph] [uidesigner] [tuning lab] [format converter] [common funcs] [web container] [uigraphics] [codeparse] [codefarm] [halcontrol] [cncparams] [hwconfig] [commucontrol] [hwdrivers] [coderuntime] [hxshell] [GVM]

The G+ system is especially suitable for complex motion systems with multi-axis linkage, such as robotic arms, multi-axis engraving machines, laser engraving machines, automated production lines, etc.

G+ language features

G+ is a modern programming language system developed by us (HongX Lab). As the object-oriented real-time and high-performance programming language, G+ can completely replace the traditional G code and ladder programming systems. It balances the modern coding features and powerful hardware operation ability along with the rich parallel control synchronization mechanism. G+ is especially suitable for industrial control and commercial applications such as CNC machine tools, multi axis engraving machines, hybrid machining centers, mechanical arms, navigation vehicles, aircraft, robots, production lines and various instruments. The G + language is interpreted and executed by the G+ virtual machine GVM.

Main advantages of G+ language

G code compatible, suitable for a variety of industrial control environments and in field programming.

Concise syntax structure and rich object types.

Powerful parallel computing / control capability and accurate synchronization mechanism.

Python language segments and C/C++ functions mixed programming.

Shielding hardware differences, object-oriented features, functions are also objects.

Cross platform, G+ virtual machine can run on X86 windows / Linux industrial control platform, portable arm Android platform, and simplified arm cortex embedded platform.