Servo motors are the key component in many fields such as model airplanes, small robots, and smart toys. The main parts of the servo motor are the DC motor and the control circuit. The traditional control circuit board only supports the PWM signal and the rudimentary control strategy that cannot make the movement smooth enough, and cannot be cascaded.

Our newly-designed control board supports several digital communications, including uart, rs485, i2c, etc., which can meet various needs. The built-in intelligent adaptive control algorithm ensures a smoother motion process, achieves higher positioning accuracy, and provides much greater output torque. This series of servo motors can support applications such as robotic arms, humanoid robots, smart toy cars, all-digital pan-tilts and drones.

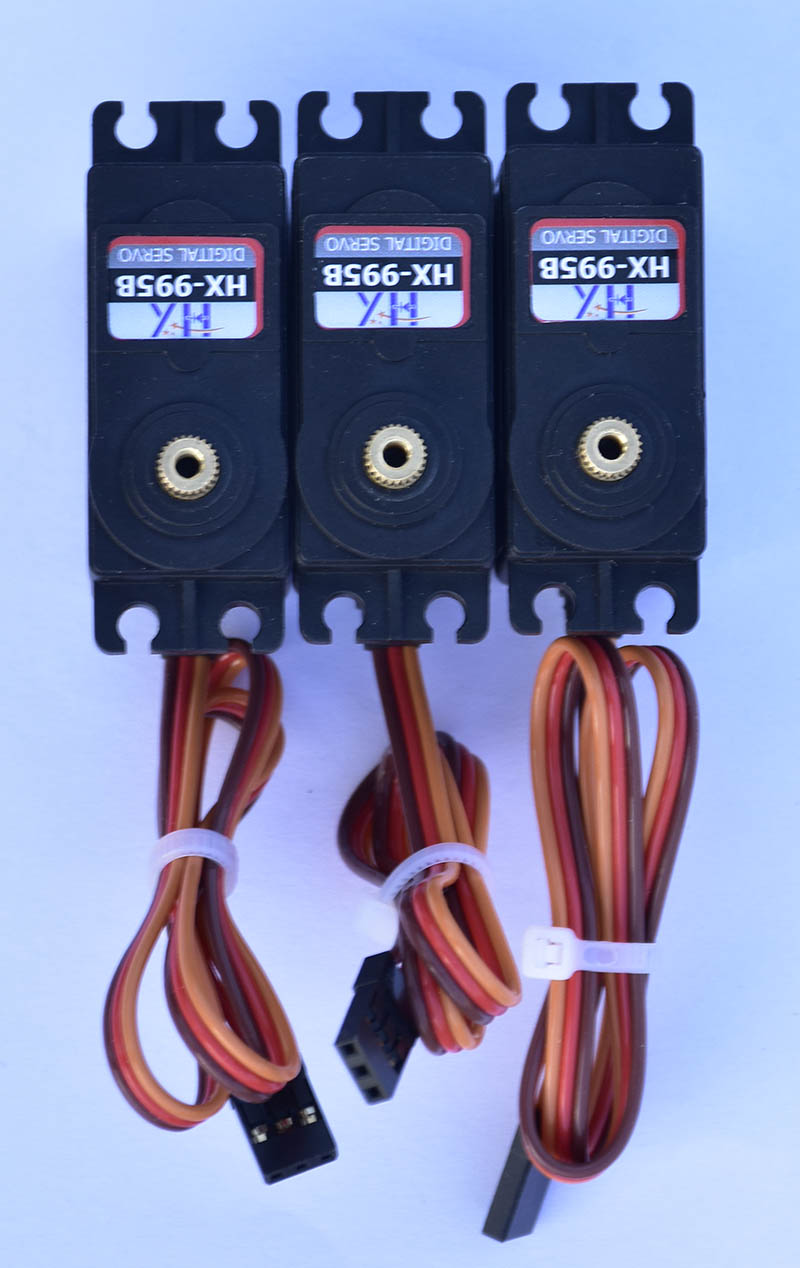

Main features of HX995:

A cascadable single-wire serial communication mode with a baudrate of up to 1Mbps (or 921600 bps).

Six operating modes.

Precise control with the position and speed can both be set to 4096 equal parts control.

The feedback value includes angular position, angular velocity and load torque.

When the internal parameters (voltage, torque and temperature) deviate too much from the working value, the alarm system will automatically deal with the problem and cancel the torque.

It uses distributed control method that the position, speed, torque and other parameters can be set through a broadcast communication frame, so that the main controller can control many servos simultaneously even if the resources of the MCU are limited.

High-quality position sensors and encoders produced in Japan have good linearity and a long lifespan.

HX995 uses all-copper gears, which have greater torque and durability, better real-time features and agility, and can ensure a smoother movement process and high positioning accuracy. With the help of HX995, players can quickly build their own robots; schools can conveniently set up robot teaching and production courses; other robot companies can use the platform for secondary development to achieve AI system behavior actuators, or promote rapid mass production of products. We provide a complete solution, including test software and test module.

Servo modes of HX995:

Position servo mode

The servo will move to the specified position and hold up at the set speed.

Curve Servo mode

By using cubic spline curve to accelerate and decelerate, it can move to the specified position more smoothly.

Flexible Servo mode

In the process of controlling the movement of the servo motor, the angle of flexible rotation can be adjusted in real time.

Continuous mode

The motor rotates continuously at a specified speed, and can be forward and reverse.

Braking mode

The motor works in the braking state, and the rotation damping is quite large.

Stop without braking mode