JSAN H6 series control cards are widely used in the CNC industry. (HongX are only the hardware supplier and do not provide third-party software.)

JSAN H6 Engraving Machine Control System comes in two versions: low-cost version and high-speed version. The maximum pulse/direction signal speed of the low-cost version is 70KHz, while the maximum speed of the high-speed version is up to 160KHz.

With the handwheel connected, the H6 high-speed version can implement remote fine adjustment and dynamic fine adjustment.

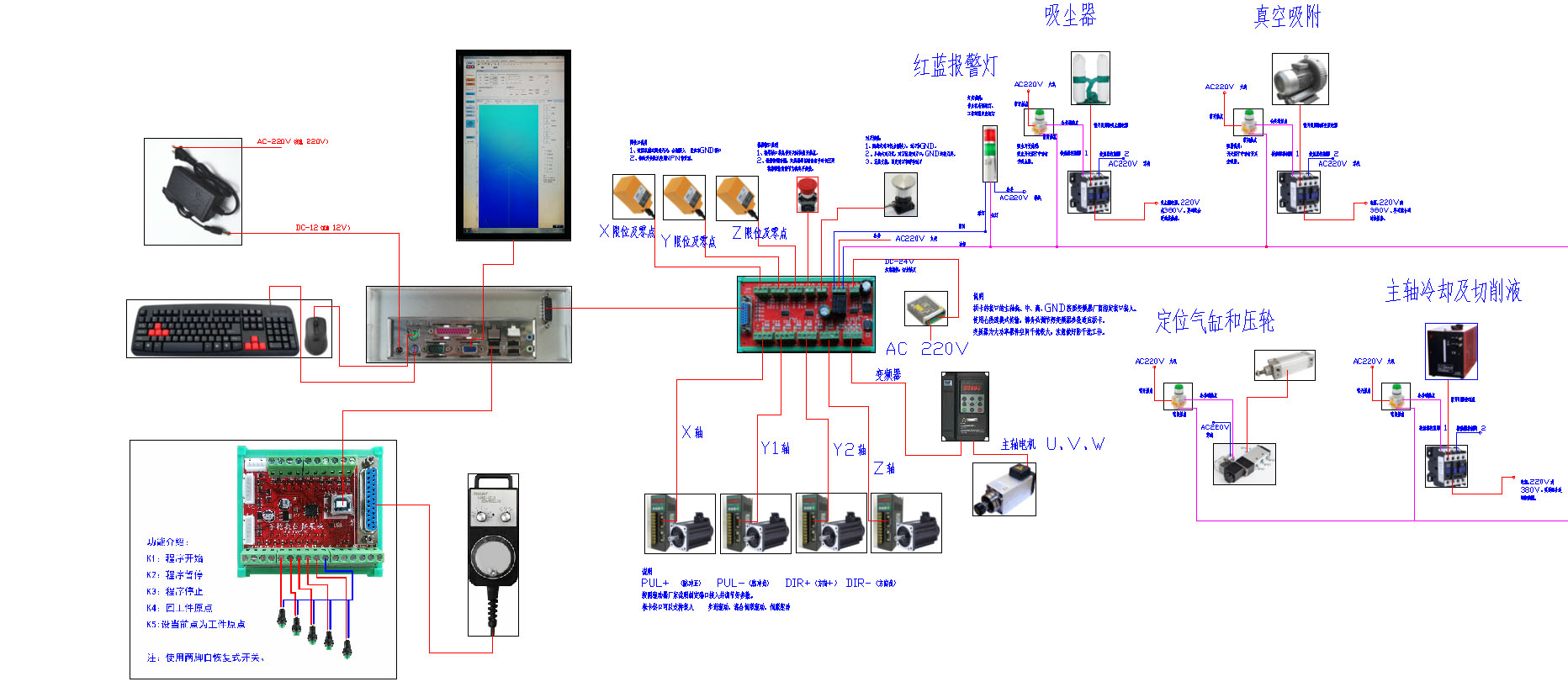

JSAN H6 Control Card adopts gold-plated PCI connector, which is reliable and durable. It uses JSAN15 dedicated port and shielded data cable to connect to the terminal blocks.

The matching terminal blocks include the mini terminal block, the standard terminal block, the relay terminal block and some other models.

The mini terminal block provides direction/pulse signal output, limit signal input, tool setting signal input, and spindle signal output, and no additional power supply is required.

The standard terminal block and the relay terminal block provide relay IO control functions and require an external 24V DC power supply.

Previous

Next

The H6 series handwheel connects to PC host software via the USB interface and connects to the handwheel handle through DB25 cables. It is completely free of drivers so it can function well as long as it is plugged.

It offers the switches of motion axis selection and scale scaling selection, which are convenient for fine adjustment and tool setting of large-scale machine movements.

The H6 handwheel can also provide the function of dynamic fine-tuning, that is, the pulse (displacement) compensation in each direction can be manually performed during the machining process without stopping the execution and modifying the G code.

In addition to various terminal boards, H6 series control cards are also equipped with the network port splitter, the network port adapters and other accessories. It is convenient to match the stepper drives and servos of different interfaces and manufacturers.

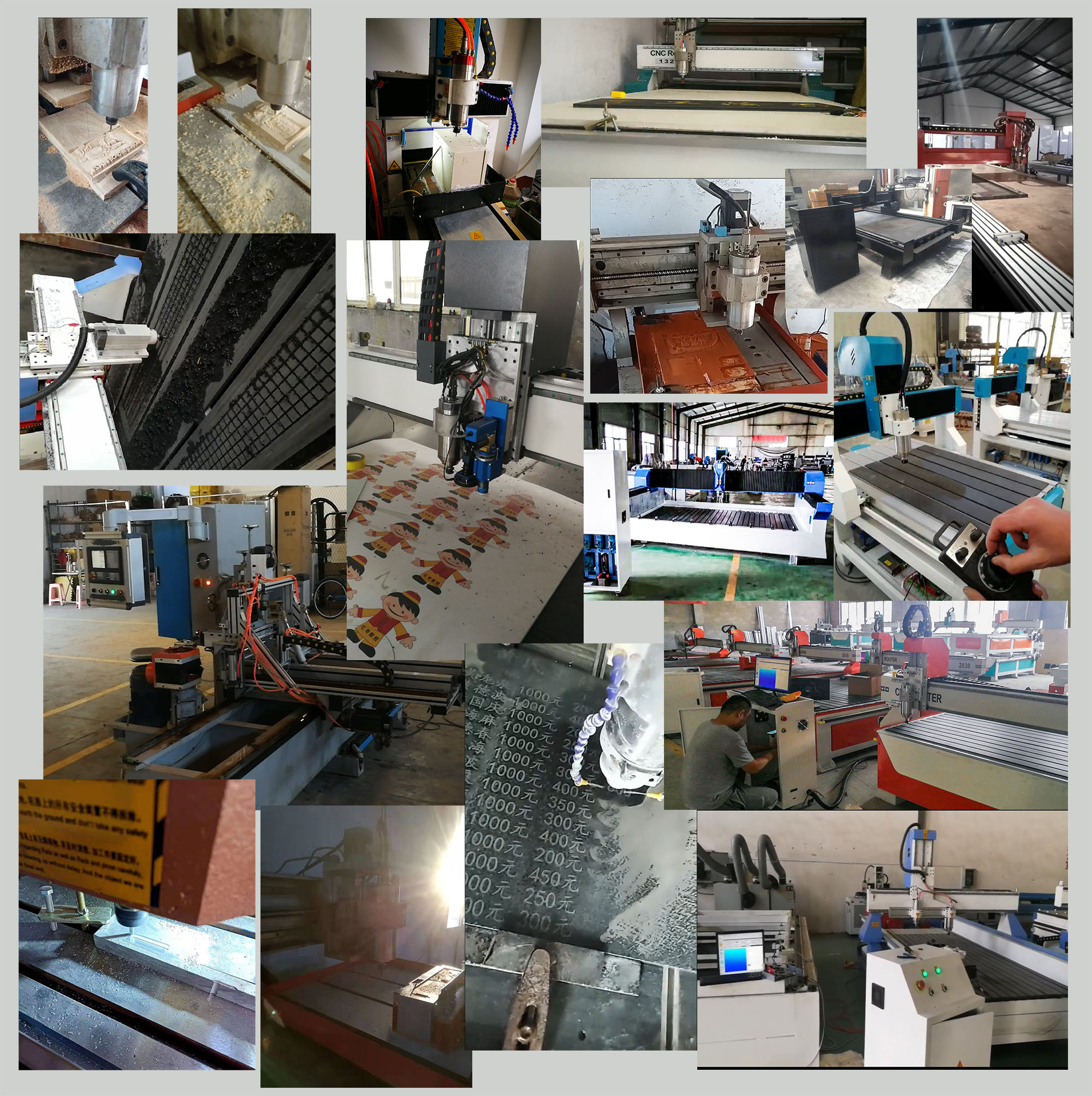

H6 series control cards provide solutions for several industries. For example: the welding control card is used to drive large welding machines and provides the function of self-learning; the relay terminal block provides convenience for controlling multiple CNC heads, water pumps, air pumps, contactors, motors, etc.

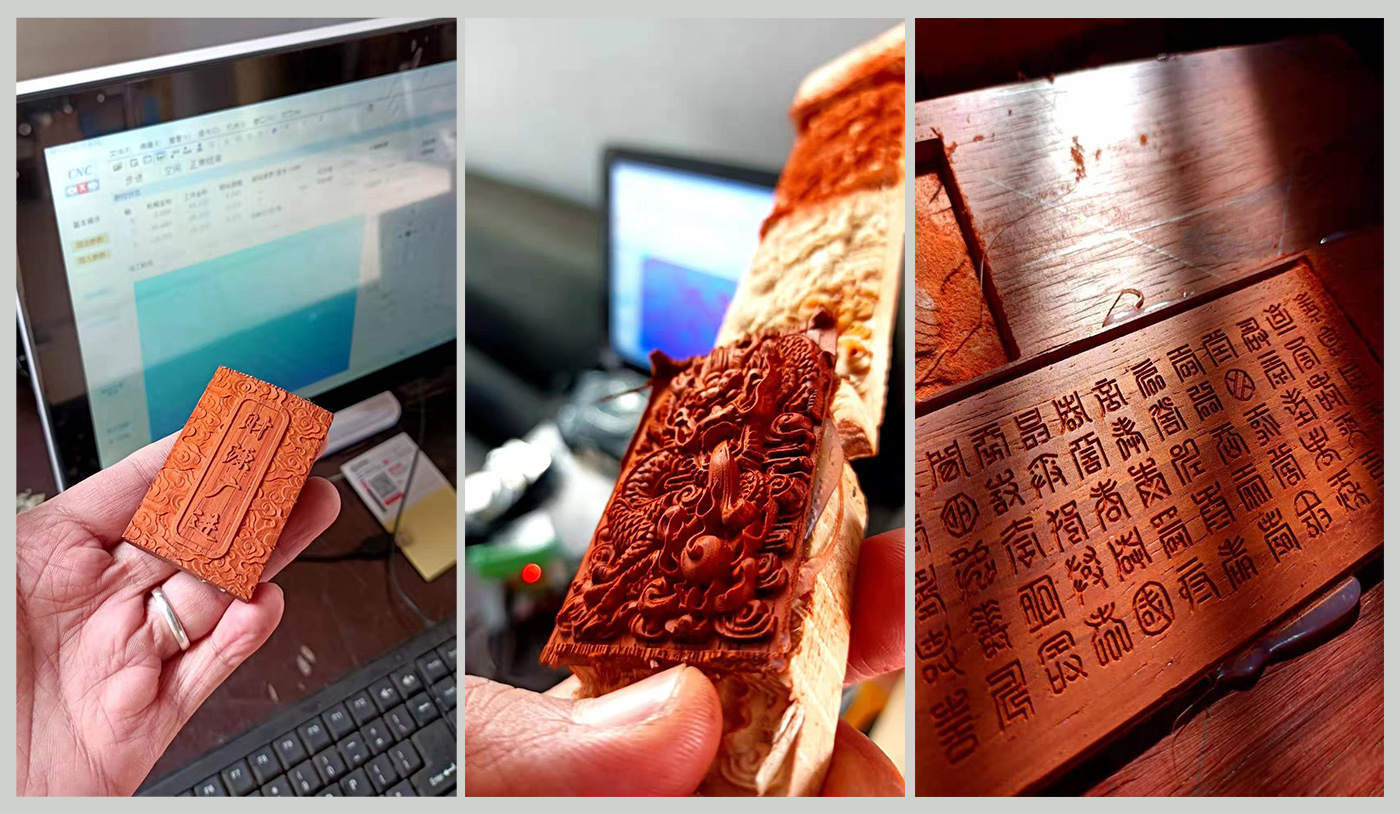

JSAN H6 Engraving Machine Control System is matched with the MCC motion control software developed by us.

MCC provides G code and G+ language programming environment, provides convenient visual parameter setting and 3D path display, and widely integrates various functions of motion process control to ensure that users can accurately grasp every processing detail.

H6 series motion control has a user bus interface, which supports customization. If your business has special requirements for motion control and IO peripheral control, please contact us to develop a special controller for you.

①Advanced system architecture: CPLD + STM32

②Excellent performance: up to 1MHz pulse baudrate (electrical limit), interpolation rate up to 70KHz/160KHz/300KHz

③Enhanced output characteristics: XYZE pulse/direction/spindle signal, up to 50mA drive current (can also be specified up to 200mA)

④More voltage level support: [XYZE pulse/direction/spindle/limit input/tool setting input] ports support 5V-24V drive mode (built-in 5V, other voltages require the standard terminal block and external power supply), covering the commonly used voltage levels of 5V/12V/24V

⑤Better protection against short circuit/misconnection/static electricity

Previous

Next

⑥High-speed digital communication interface: can be used to connect the main card to the adapter board, multi-process driver board, extended operation board, compatible protocol drivers and inverters, etc.

⑦Analog spindle signal output: (5V/10V optional) hardware support

For more information, please refer to the H6 project introduction.

①Support vendor permission encryption

②Support test pulse output

③Support both manual and automatic multi-process

④Support application function expansion

If you need more detailed technical information about wiring diagram of H6 Control System, please contact us. (The software shown on this page is not necessarily HongX’s product, but is only used to show the system connection.)